Rubber profiles are the most widely used and manufactured forms of rubber extrusions, and some manufacturing companies deal solely in custom extrusion profile orders, which is quite profitable. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber values quality, consistency, and fast delivery of our products. Our components are made from a variety of elastomers such as neoprene and silicone, and our team members are capable of turning your drawing into the part you need. Contact us today to tell us about your next project!

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

More Rubber Profile Manufacturers

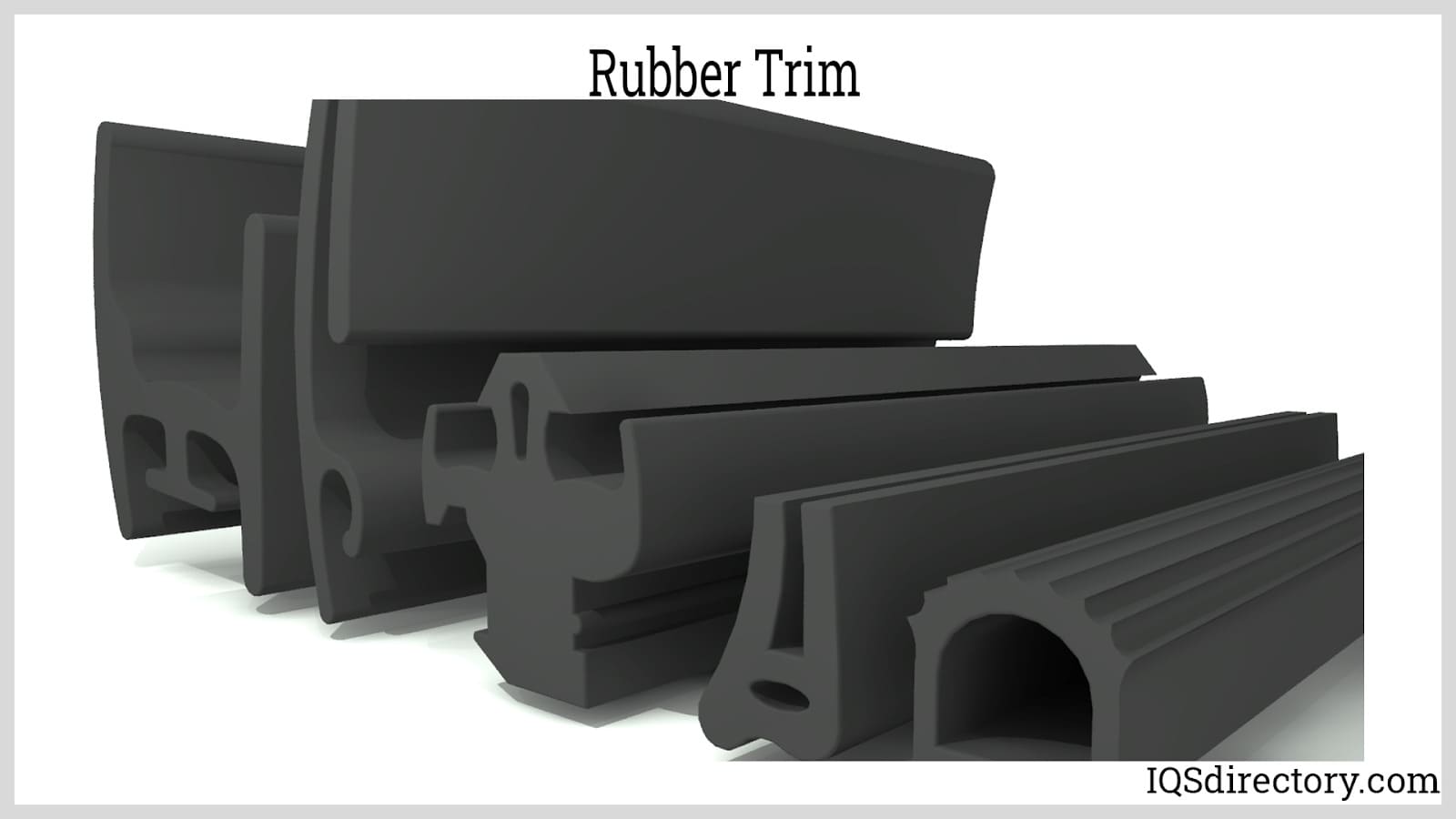

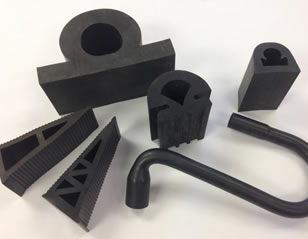

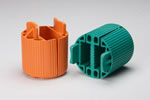

Custom extrusion profiles are used in a very large variety of industrial applications including the aerospace industry, automotive parts industries, medical technology industries and industrial, commercial and residential building. Long, thin extruded profiles are often used as trim, weatherstripping or other types of insulation. Profiles can also be made hollow so that cords or wires can pass through them.

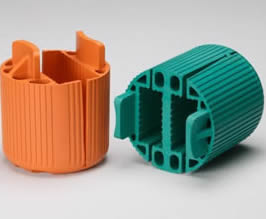

They can be made into sheets, tubes, plates, channels, bars, films and other shapes. They can feature simple cross-sections or complex patterns; they can be square, round, u-shaped, t-shaped or any other configuration. The only determining factor in profile design is need; because of the modularity of extruders and the extrusion process, there are few limits to the number of different profile shapes that can be produced. A rubber profile is made by passing raw natural or synthetic rubber material through a rubber extruder.

Most extrusion lines begin with a collection of raw rubber material, or stock, that is passed through a hopper and directed into a conveyance channel. Within most rubber extrusion conveyance channels is a screw that pressurizes the rubber as it is heated. As the rubber passes through the conveyance channel, it becomes semi-liquefied. At that point it is ready to pass through the die. A die is a tool that is used to mold a raw material into a usable form. A die can be configured in any shape, and for this reason an extruded rubber profile can take any shape.

The semi-liquefied rubber is simply forced into the die, and when it emerges it cools, hardens and is ready to be cut and shipped. Most varieties of rubbers can be extruded; depending on the raw materials' composition, the process requires different processing times and temperatures. Silicone rubber, for example, requires higher temperatures to be become liquefied. If the profile requires additional treatment for improved strength or durability, a number of curative or treatment procedures may be performed to enhance the suitability of the extrusion for a particular application.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

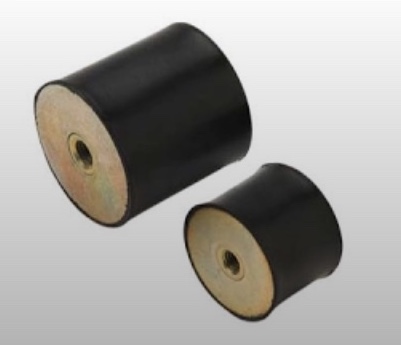

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services