Rubber edge trim is a commonly used product in various industries. It serves as a protective barrier for the edges of sharp or rough materials, providing a secure seal that prevents dust, debris, and moisture from getting inside the gap between two surfaces. In this article, we will discuss the creation, variation, challenges, benefits, and applications of rubber edge trim. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber values quality, consistency, and fast delivery of our products. Our components are made from a variety of elastomers such as neoprene and silicone, and our team members are capable of turning your drawing into the part you need. Contact us today to tell us about your next project!

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

More Rubber Edge Trim Manufacturers

Processes Used to Create Rubber Edge Trim

Rubber edge trim can be manufactured using two main processes: extrusion and molding.

Extrusion

Extrusion involves pushing a rubber material through a die that has a specific shape. The rubber material is first heated to a molten state and then forced through the die, which creates the shape of the trim. The trim is then cooled and cut to the desired length.

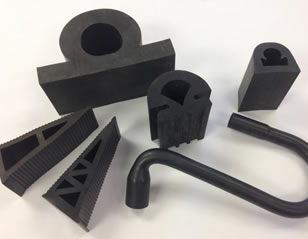

Molding

Molding, on the other hand, involves shaping a rubber material by heating it and then cooling it in a mold. The rubber material is first placed in a mold that has the desired shape, and then it is heated to a temperature that allows it to take the shape of the mold. Once the rubber has cooled and solidified, the trim is removed from the mold. However, it is a more expensive process compared to extrusion, and it also requires more time and resources to set up.

Choosing between These Methods

The choice of process will depend on specific factors related to the application. Here are a few general guidelines:

Extrusion is typically used for applications where a continuous length of rubber edge trim is needed, such as in the construction and automotive industries. This is because extrusion can produce long lengths of uniform trim quickly and efficiently, making it a cost-effective solution for large volume production. Extrusion is also ideal for applications where the trim has a simple, straight shape or a consistent cross-section.

Molding, on the other hand, is typically used for applications where a more complex or customized shape is required, such as in the manufacture of consumer goods or medical equipment. Molding allows for greater design flexibility and precision in the shape of the trim, making it ideal for smaller volume production runs or specialized applications. Molding is also ideal for applications where the trim needs to have a specific texture or finish, such as a smooth or glossy surface.

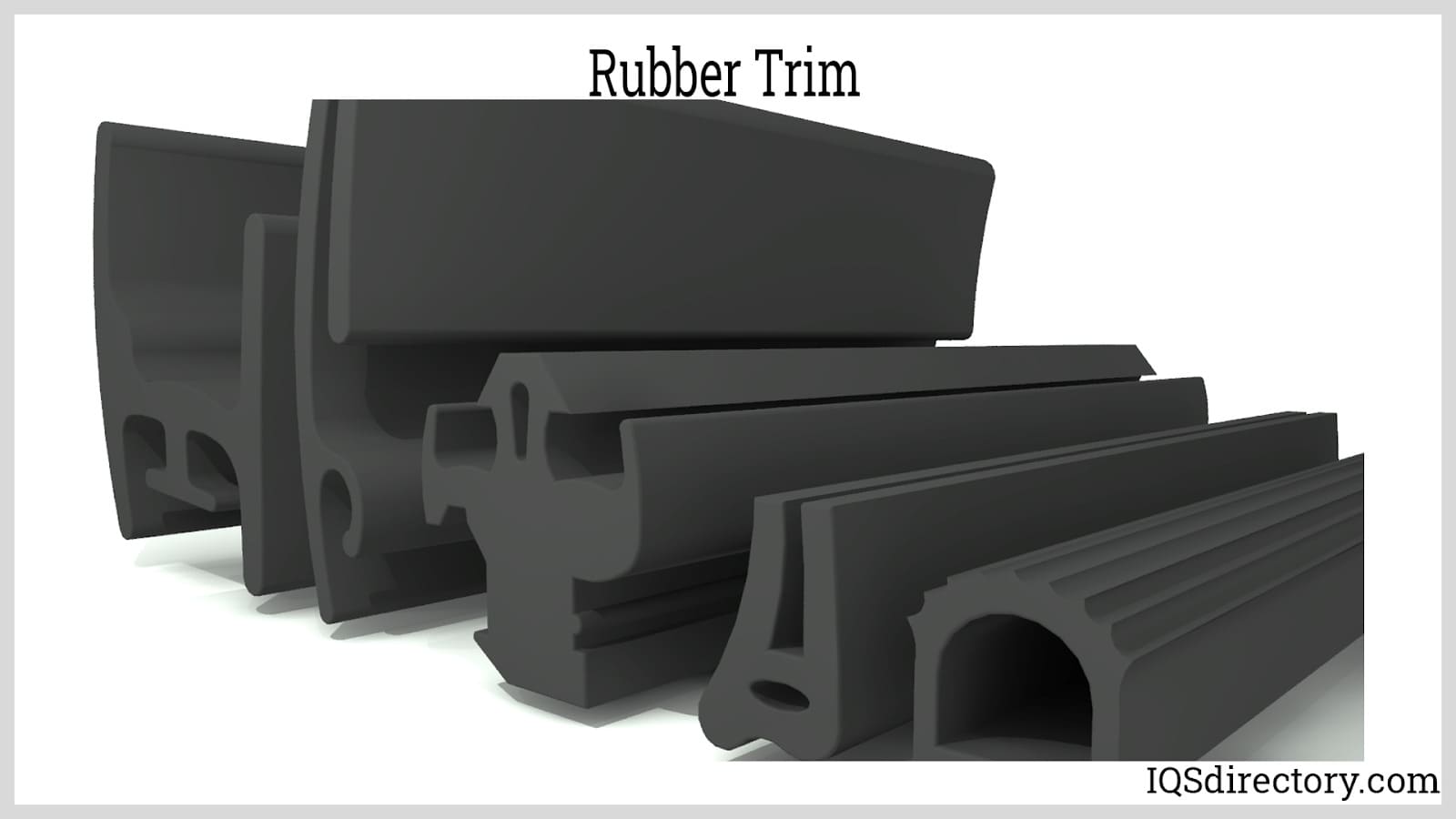

Variation in Rubber Edge Trim

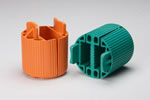

Rubber edge trim can come in a variety of shapes, sizes, materials, and other classifications depending on the specific application. These variations in rubber edge trim allow manufacturers to choose the best product for their specific needs, taking into account factors such as material properties, durability, and cost. Here are some of the variations that can be found:

Profile Shape

Rubber edge trim can have a variety of profile shapes, including round, square, rectangular, and custom shapes.

Size

Rubber edge trim can vary in size, from small trim pieces used for consumer products to larger pieces used in construction or automotive applications.

Material

Rubber edge trim can be made from a variety of materials, including EPDM, neoprene, silicone, and PVC, each with its own unique properties and advantages.

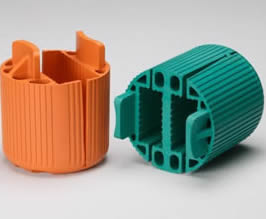

Color

Rubber edge trim can come in a range of colors, depending on the material used and the specific requirements of the application.

Texture

Rubber edge trim can be smooth, textured, or have a specific pattern or finish.

Adhesive Backing

Some rubber edge trim comes with adhesive backing, which allows for easy installation and a secure, long-lasting bond.

Challenges Related to Rubber Edge Trim

The challenges associated with rubber edge trim are mainly related to the manufacturing process. For instance, the trim may need to meet specific requirements in terms of size and shape. Additionally, the trim may need to be able to withstand certain environmental factors such as heat, moisture, and UV exposure.

Benefits of Rubber Edge Trim

Rubber edge trim has several benefits, including:

Durability and Long Lifespan

Rubber edge trim can withstand extreme temperatures, chemicals, and wear and tear, ensuring that it lasts for a long time.

Protection against Impact and Wear

Rubber edge trim can provide a protective barrier against impact and wear, which is essential in preventing damage to the surface being protected.

Aesthetic Appeal

Rubber edge trim comes in various colors and shapes, which can enhance the aesthetic appeal of a product.

Noise Reduction

Rubber edge trim can help reduce noise by providing a cushion between two surfaces.

Applications of Rubber Edge Trim

As a result of these benefits, rubber edge trim has a wide range of applications, including:

Automotive Industry

Rubber edge trim is used in vehicles to protect the edges of windows, doors, and trunks.

Construction Industry

Rubber edge trim is used in the construction industry to seal gaps between materials and prevent moisture and dust from getting inside.

Furniture Manufacturing

Rubber edge trim is used in furniture manufacturing to provide a protective barrier between materials and prevent wear and tear.

Electrical and Electronics Industry

Rubber edge trim is used in electrical and electronics manufacturing to protect wires and cables from damage.

Marine Industry

Rubber edge trim is used in the marine industry to protect boat edges and hatches from water and salt.

Choosing the Correct Rubber Edge Trim Manufacturer

To ensure you have the most productive outcome when purchasing rubber edge trim from a rubber edge trim manufacturer,it is important to compare several companies using our directory of rubber edge trim manufacturers. Each rubber edge trim manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each rubber edge trim business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple rubber edge trim companies with the same form.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

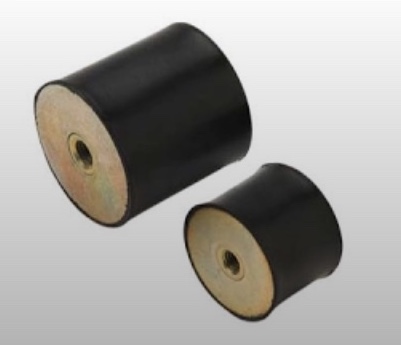

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services