There are a variety of different methods that can be used in order to boost these different physical traits and properties depending on the needs of the customer and the capabilities of the rubber channel manufacturer. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber values quality, consistency, and fast delivery of our products. Our components are made from a variety of elastomers such as neoprene and silicone, and our team members are capable of turning your drawing into the part you need. Contact us today to tell us about your next project!

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

More Rubber Channel Manufacturers

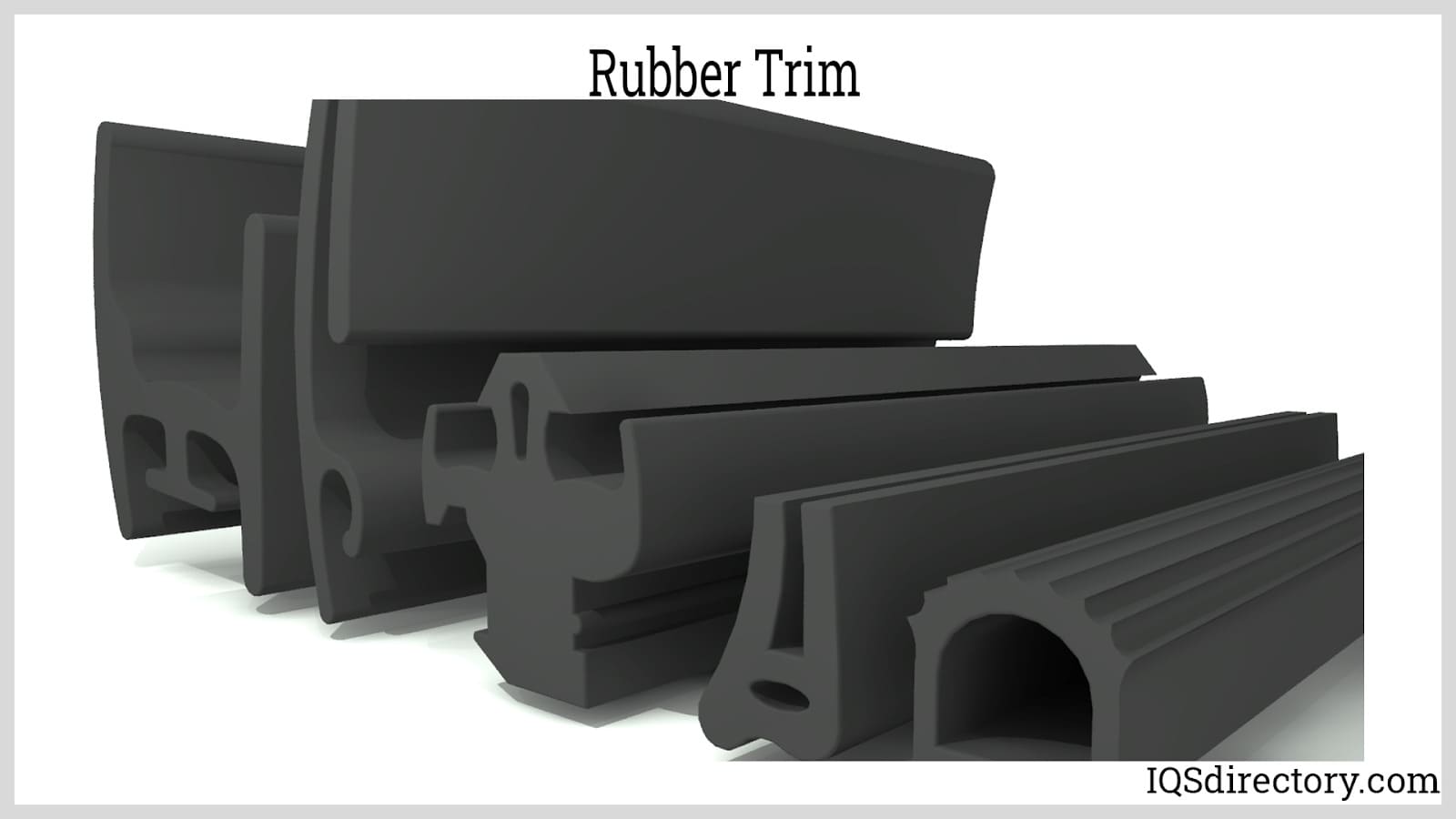

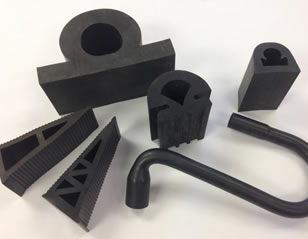

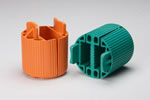

Rubber channels are most commonly created using extrusion processes, and they can be used for a wide range of applications such as noise control, vibration control, and even just decorative trim. No matter your needs, it is important to fully research different rubber channel manufacturers and the capabilities that they have in order to receive the best possible product.

Rubber channels are manufactured through the rubber extrusion process which is a process where a rubber blank is forced through a die in order to shape it into the final desired product. This process can be used for a wide range of materials from metals and ceramics to food products, think of how sausages are made and that is essentially the rubber extrusion process.

However, if you are searching for high quality rubber channels it is best to go with a company that specializes in rubber extrusions as they will know how to work with the material in order to ensure that all of your expectations, specifications and requirements are met. The reason why the extrusion process is used over any other form of manufacturing is that through the use of extrusion the final product can be in great lengths which is typically something that is coveted when dealing with rubber channels.

Whatever your application may be, finding the right manufacturer is the difference between an average product and a great product. Be sure to fully understand what it is you are looking for in your final product and how and where you will be using the product as all these considerations will factor into the material choice and process that your manufacturer may use when creating your rubber channel.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

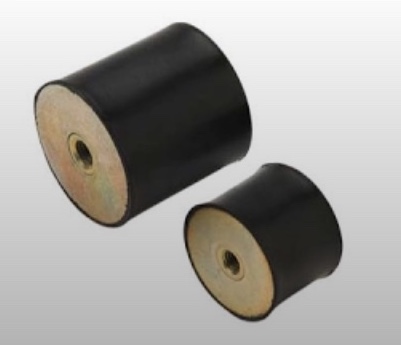

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

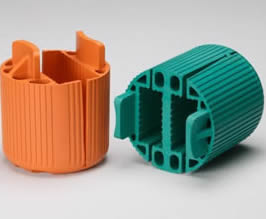

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services