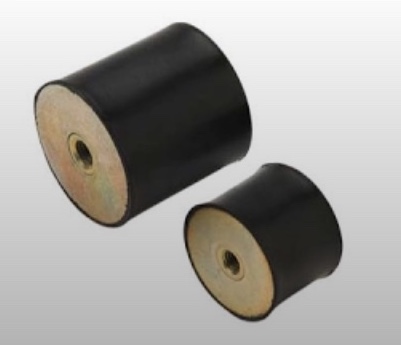

A rubber bushing, also called a vibration isolator, provides a flexible interface between two rigid pieces. These bushings serve as a buffer to keep two pieces apart while allowing for some mobility—this aids in reducing the annoyance caused by machine noise and vibration. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber values quality, consistency, and fast delivery of our products. Our components are made from a variety of elastomers such as neoprene and silicone, and our team members are capable of turning your drawing into the part you need. Contact us today to tell us about your next project!

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

More Rubber Bushing Manufacturers

To prevent wear and damage, connected elements must not move or vibrate, which is a crucial part of a rubber bushing's function. Rubber bushings are durable tools that can tolerate high tension and severe deformation.

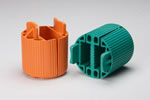

There are numerous variations of rubber bushings. They are made of both natural and synthetic rubber. Since natural rubber and synthetic rubber have different properties, the type of rubber chosen will dictate how the bushing can be used. They are often made into an annular cylinder shape and enclosed in outer tubes or metal enclosures. An internal crush tube shields the bushings in other applications from crushing.

Types of Rubber Bushings

Cone Rubber Bushings

A type of vibration isolator known as a cone rubber bushing or conical bushing is a contract between two components. This bushing is frequently used in submersible pumps. It is created with ceramic materials and cutting-edge procedures, and it is also evaluated on several different factors. This bushing, which comes in several sizes, is well-liked for its dependability and excellence. Conical rubber bushings are created using silicone rubber with a lower compression set. The silicone material can endure extremely high temperatures and resist grease and oil. Conical bushings have a high load capacity and are excellent for compression and shearing loads.

Cylindrical Bushes

Cylindrical bushes are available as press-fit (flanged), push-fit (bushed), and loose fits requiring nuts, bolts, and washers. They are good for axial, radial, and torsion loads. Although they have numerous additional uses, such as in sugar beet raising machines, field sprayers, road sweepers, and racing cars, cylindrical bushes are principally employed for steering systems in road vehicles.

Pivot Bush

The purpose of this kind of bush is to provide the least amount of torsion resistance. Therefore, only one of the armatures is attached to the elastomer, and a sufficient permanent lubricant guarantees very little torsional resistance between the elastomer and the other armature.

Flanged Bushing

A sleeve bushing with one end flanged and extending laterally outward is known as a flanged bushing. They are made of ethylene propylene diene monomer (EPDM) or styrene butadiene rubber (SBR). The flanged portion of flanged bushings functions as a washer, allowing them to support axial loads. There are several industrial and anti-vibration uses for a flanged bush.

Spherical Bushes

Spherical bushings are self-aligning plain bushings with spherical sliding surfaces on their inner and outer rings. They can simultaneously support a heavy axial load and a large radial load. In addition, they can correct for misalignment and are made for gradual swinging motion.

Applications of Rubber Bushings

- Rubber bushings are frequently preferred to solid connections because they produce less noise and vibration. They may also render lubrication between two parts unnecessary.

- Rubber bushings, as part of a vehicle's suspension system, can negatively impact how the car handles, particularly during cornering and braking.

- Rubber bushings are frequently employed in the manufacture of automobiles. Typically, they are found in gear sticks, double wishbone suspensions, anti-roll bars, shock absorber mountings, and internal combustion engines in some autos.

- They are also employed in skateboards, where they help turn the board and tilt the trucks. Rubber bushings act as another way to distribute stress within a structure and lessen strain.

- These bushings can also be abrasion resistors, resonance isolators, or dampers. Rubber bushings are seals that can be used with cables, pipelines, and tubing.

Advantages of Using Rubber Bushes

Eliminate the need for lubrication

Rubber bushings eliminate the requirement for lubrication in the gap between two components.

Reduced machinery wear

Rubber bushings keep parts from rattling against one another, reducing wear and tear on the equipment and providing a safer working environment for the employees' eardrums.

Lessen noise

Rubber bushings lessen noise in industries from mechanical contact.

Can be custom-made

Rubber bushings can be custom-made so they can work at their best in their intended application.

Reduced maintenance

Rubber bushings require less maintenance because they have a long, maintenance-free service life and can be used in one's products and machines.

Choosing the Proper Rubber Bushings Manufacturer

To make sure you have the most beneficial outcome when purchasing rubber bushings from a rubber bushings manufacturer, it is important to compare at least 4 to 5 companies using our list of rubber bushing manufacturers. Each rubber bushing manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber bushing company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rubber bushing companies with the same form.

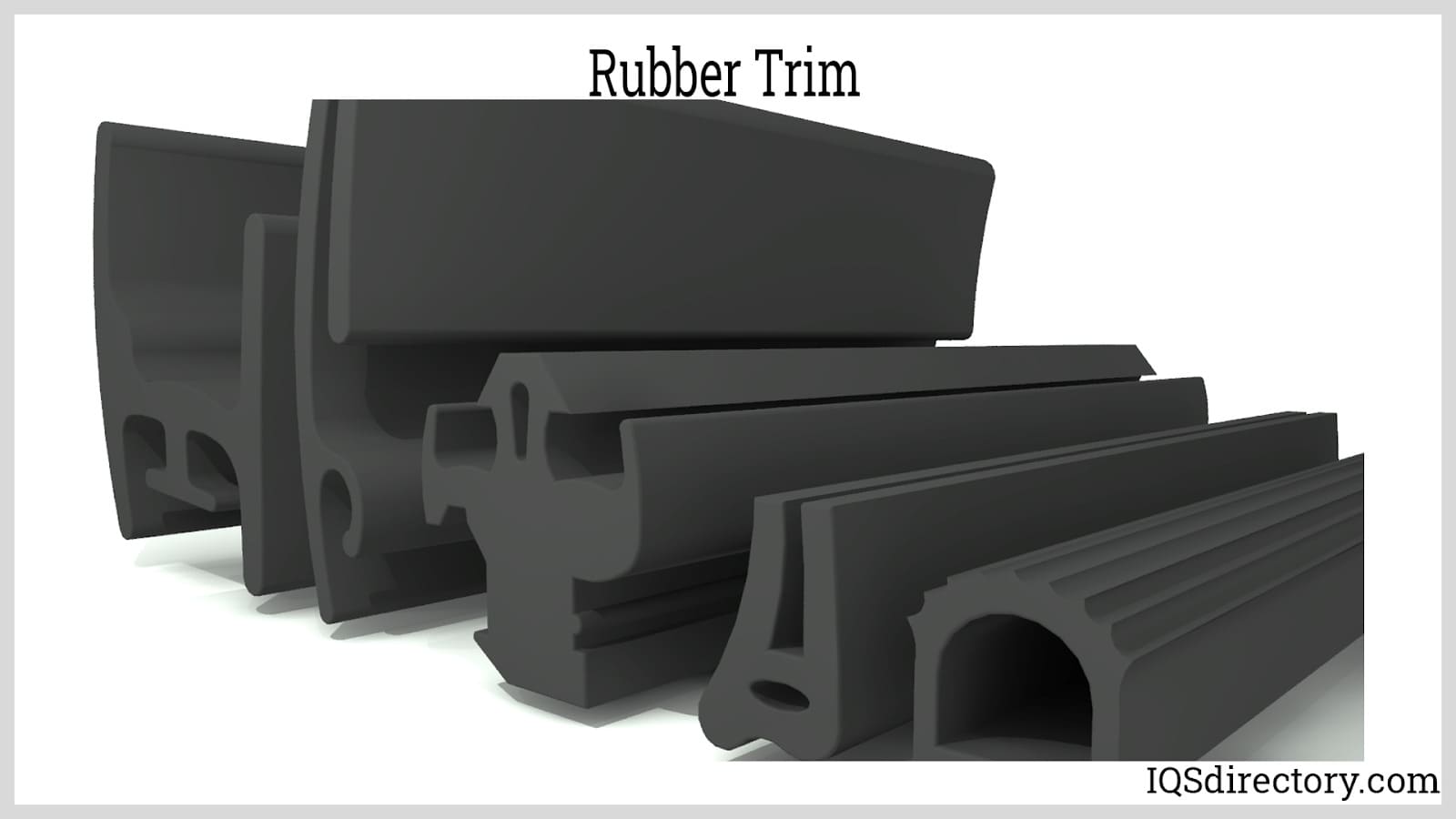

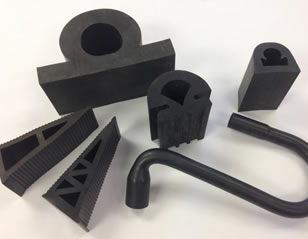

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services