Rubber extrusion is the process of shaping rubber materials into a certain shape. Manufacturers utilize a rubber extruder machine to create this form. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber values quality, consistency, and fast delivery of our products. Our components are made from a variety of elastomers such as neoprene and silicone, and our team members are capable of turning your drawing into the part you need. Contact us today to tell us about your next project!

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

More Extruded Rubber Manufacturers

What is Extruded Rubber?

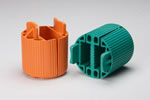

Extruded rubber refers to specially shaped rubber components manufactured through the process of rubber extrusion. This process utilizes a heated shearing screw conveyor and a custom die, which together form the core of every rubber extruder. Under significant pressure, the extruder forces uncured rubber compounds into the die, shaping the material according to the intended cross-sectional profile.

Typically, soft, unvulcanized rubber compounds—such as EPDM rubber, neoprene, silicone, nitrile, and natural rubber—are inserted into the extruder. The extrusion process keeps the rubber malleable, which is ideal for forming intricate shapes and profiles. However, for most extruded rubber products to achieve their final properties, they must undergo vulcanization or curing. This process hardens the rubber, enhancing its durability, elasticity, and resistance to environmental factors.

Rubber extrusion is widely used in the manufacturing of seals, gaskets, weatherstripping, tubing, and a variety of custom rubber profiles. These extruded rubber components are indispensable in industries such as automotive, construction, aerospace, electrical, marine, and industrial equipment manufacturing. If you’re looking to source custom extruded rubber profiles or need technical advice on material selection, understanding the basics of rubber extrusion can help inform your buying decisions.

Are you wondering how to choose the right extruded rubber material for your application? Explore our detailed material selection guides or speak directly with a specialist to compare EPDM, silicone, neoprene, and other rubber compounds based on your project’s environmental and mechanical requirements.

The Rubber Extrusion Process Explained

The rubber extrusion process begins with feeding a pre-mixed rubber compound into the extruder. This compound enters a feed hopper, which steadily delivers the material into the rotating screw’s flutes. As the screw turns, it pushes the rubber forward, subjecting it to increasing pressure and temperature as it approaches the die.

When the material reaches the extrusion die, the built-up pressure forces it through precision-shaped apertures. Due to the viscoelastic nature of rubber, the extruded material typically expands upon exiting the die. The degree of expansion or shrinkage during and after extrusion depends on factors such as the specific rubber compound, its hardness (durometer), and the curing process.

Manufacturers must account for dimensional changes by specifying plus-or-minus tolerances on cross-sections and lengths. After extrusion, the product is usually vulcanized—either in a continuous cure system (like a steam tube or salt bath) or in an autoclave—to stabilize its shape and physical properties. During vulcanization, the rubber may shrink more in the center of the extrusion than at the ends, making precise quality control essential.

Want a deeper understanding of how extrusion variables affect finished rubber products? Read our technical articles on process optimization, or ask about how temperature, die design, and curing methods impact product consistency and performance.

Die Design for Rubber Extrusion

A rubber extrusion die is a highly engineered tool made by machining a specific-shaped hole into a steel blank. The shape and dimensions of this opening determine the profile of the finished extruded rubber product. Precision die design is critical, as even slight inconsistencies can lead to defective or out-of-tolerance parts.

As the rubber is driven through the die by the extruder’s screw, it often swells due to its inherent properties. To ensure dimensional accuracy, each extrusion die is custom-fabricated based on the unique requirements of the part and the rubber compound being used. This customization allows manufacturers to create complex profiles such as tubing, O-rings, weatherstripping, and custom gaskets.

Advanced die technologies—including CAD/CAM modeling and CNC machining—enable the rapid prototyping and production of dies for both standard and highly specialized applications. If you have a unique sealing or insulation challenge, a customized die can deliver the exact shape and material properties you need.

Curious about custom die design for your product? Contact our engineering team to discuss your cross-sectional requirements, or browse our case studies for examples of successful custom extruded rubber solutions.

Lathe Cut Rubber: Precision Manufacturing

Lathe cutting is a secondary process used to produce high-precision rubber components from extruded tubes. The process involves extruding a rubber tube, trimming it to a preliminary length, sliding it onto a mandrel, curing the material, grinding the outside diameter (OD) for tolerance, and finally cutting the component to its finished length on a lathe.

This manufacturing method is ideal for producing washers, gaskets, and seals requiring tight tolerances and square-cut or custom-edged profiles. Lathe cutting is compatible with a wide range of elastomeric materials, including EPDM, neoprene, silicone, and fluoroelastomers, making it suitable for demanding environments where chemical resistance, temperature stability, or low compression set are critical.

Lathe cut rubber is frequently used in applications ranging from small washers for plumbing and automotive assemblies to large gaskets for drums, tanks, and industrial enclosures. The process is particularly cost-effective for high-volume production runs, delivering consistent quality and dimensional accuracy at scale.

Need high-precision rubber washers or gaskets? Discover our range of lathe cut rubber products or request a quote to compare material options and lead times for your application.

Mandrel Formed Tubing: Complex Shapes and Bends

Mandrel forming is a specialized process for creating rubber tubing with precise bends and complex geometries. First, a tube is extruded to the required inner and outer diameters and cut to length. Next, the tube is inserted—often manually or with automation—onto a mandrel shaped to match the final product’s design. This “sticking” process ensures the tubing adopts the mandrel’s curves and bends without kinking or collapsing.

For high-volume manufacturing, racks of mandrels loaded with rubber tubes are moved into an autoclave for curing. After vulcanization, the tubes are removed, cleaned to eliminate any release agents, and cut to their final length. Mandrel formed tubing is essential for products that require consistent inner diameters and smooth, uninterrupted bends, such as automotive coolant hoses, medical tubing, and industrial fluid transfer lines.

This process is ideal for both simple 90-degree bends and intricate multi-bend configurations, making it a preferred choice for custom hose assemblies and specialty fluid handling applications where standard straight tubing would fail.

Have questions about mandrel formed tubing for your project? Speak with our technical sales engineers or explore our tubing customization options for automotive, medical, and industrial use cases.

Applications of Extruded Rubber Products

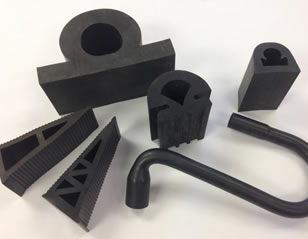

Custom extruded rubber products offer unmatched versatility across industries. By tailoring lengths, shapes, and rubber compounds, manufacturers can deliver components that meet demanding temperature, weather, chemical, and mechanical performance requirements. The extrusion process enables the production of both dense and sponge rubber profiles, making it easy to balance flexibility, sealing, and cushioning properties.

Common materials include EPDM, neoprene, silicone, nitrile, and natural rubber. These compounds can be formulated for superior UV resistance, ozone resistance, temperature stability, and chemical compatibility. Typical extruded rubber products include:

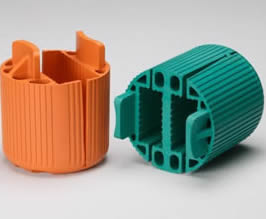

- Electrical and mechanical connectors

- Rubber tubing for fluid transfer and insulation

- Mandrel hoses for automotive, marine, and industrial applications

- Seals for doors, cabinets, windows, and enclosures

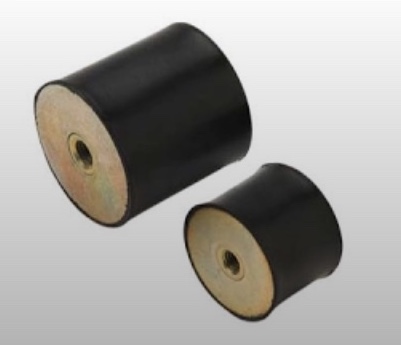

- Vibration and acoustic dampeners

- Gaskets and spliced gaskets for leak-proof joints

- Window sealing for public transportation and architectural glazing

- Pressure switch square tubes

- Weatherstripping profiles for residential and commercial construction

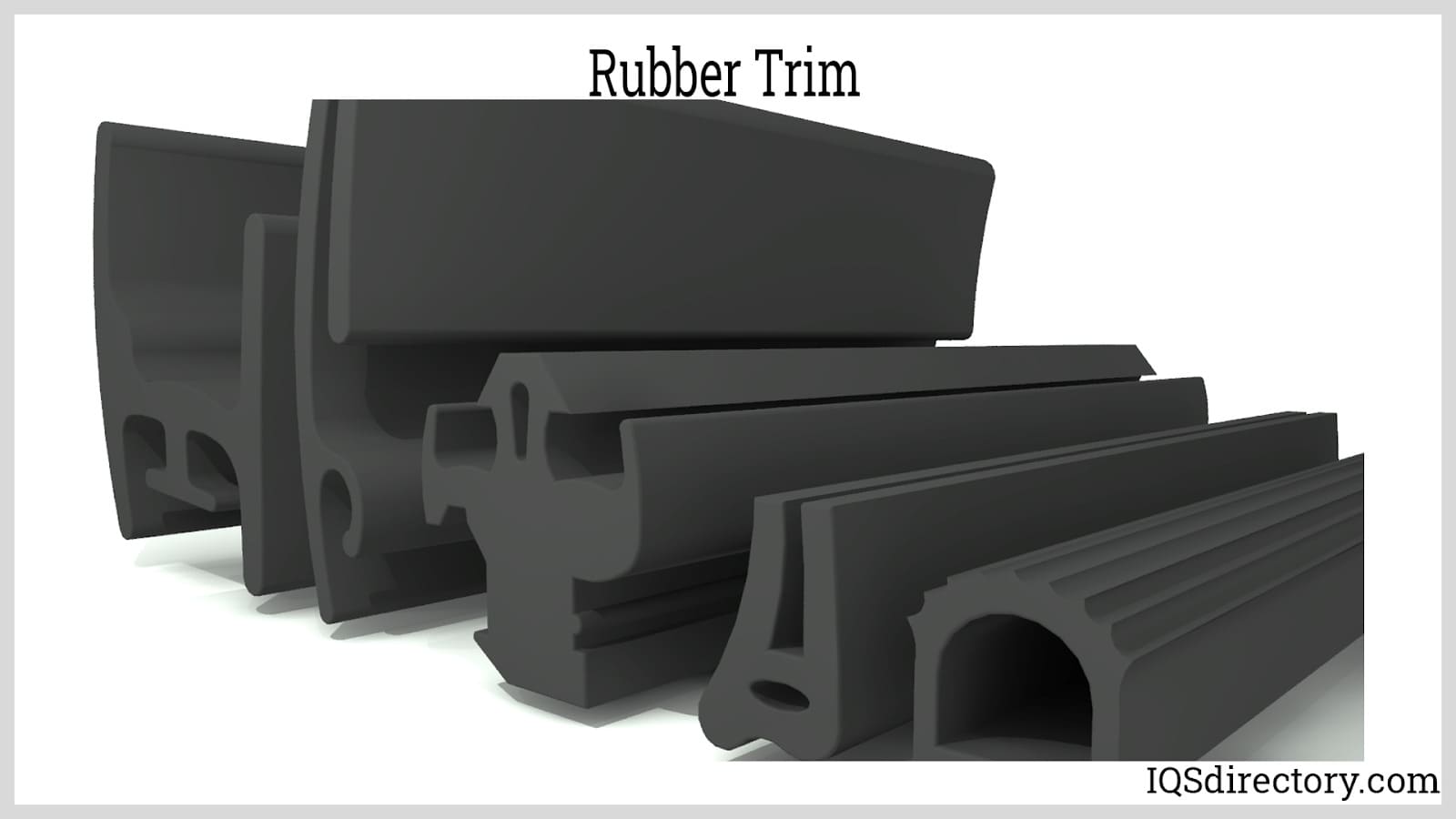

- Protective edge trims for sheet metal and glass

- Custom bumper guards and corner protectors

- Extruded rubber O-rings and cord for static or dynamic sealing

- Medical device components and sterilizable tubing

Extruded rubber’s adaptability makes it the material of choice for sealing, cushioning, insulating, protecting, and connecting in a host of demanding environments. Whether you need a simple D-shape seal for a window or a complex multi-void profile for vibration isolation, extrusion offers almost limitless design possibilities.

Searching for a specific extruded rubber application? Use our interactive product finder or contact our applications engineering team to identify the best solution for your project.

Benefits and Advantages of Rubber Extrusion

The rubber extrusion process delivers a host of compelling advantages, making it the preferred method for manufacturing many rubber components:

- Design Flexibility: Easily produce a wide variety of forms, profiles, and cross-sections, including custom, intricate, or multi-material designs.

- High Efficiency: Continuous manufacturing results in cost-effective production, ideal for both short runs and high-volume orders.

- Material Variety: Compatible with numerous rubber compounds, allowing for precise tailoring of mechanical, chemical, and environmental properties.

- Consistent Quality: Modern extrusion and curing methods ensure reliable, repeatable dimensions and performance.

- Minimal Waste: Optimized processing and die design reduce scrap material, lowering costs and supporting sustainability initiatives.

- Lightweight & Flexible: Finished products offer excellent flexibility and low weight, simplifying installation and handling.

- Scalability: From prototyping to mass production, extrusion accommodates a wide range of order sizes and timelines.

Rubber extrusion is also an environmentally friendly choice, as many compounds can be formulated with recycled content and the process itself generates less waste. For companies focused on sustainable manufacturing and lean production, extrusion is a smart option.

Interested in the benefits of extruded rubber for your business? Request a free consultation or download our white paper on cost savings and performance improvements with custom rubber extrusion.

Buyer’s Guide: Selecting the Right Extruded Rubber Supplier

Selecting a reliable extruded rubber manufacturer is a critical step in ensuring product quality, cost-effectiveness, and on-time delivery. Here are key factors to consider when evaluating potential suppliers:

- Technical Expertise: Does the supplier have experience with your required rubber compounds and profile geometries?

- Customization Capabilities: Can they provide tailored die design, prototyping, and secondary finishing (such as splicing, cutting, or adhesive backing)?

- Quality Control: What certifications, inspection protocols, and process controls are in place to ensure dimensional accuracy and material conformity?

- Production Capacity: Are they equipped to handle both small batch and high-volume orders, with flexible lead times?

- Value-Added Services: Do they offer design assistance, material selection support, and logistics solutions?

- Pricing and Lead Times: Are quotes competitive and timelines reliable? Do they offer transparent costing and order tracking?

- Industry Reputation: What do reviews, testimonials, and case studies reveal about past performance and customer satisfaction?

To ensure you achieve the best outcome when purchasing extruded rubber products, it's recommended to compare at least four suppliers using our extruded rubber supplier directory. Each supplier profile highlights their specialties, technical capabilities, and provides a direct contact form for RFQ submissions. Utilize our website previewer to quickly evaluate supplier sites, and leverage our streamlined RFQ form to request quotes from multiple manufacturers simultaneously.

Ready to get started? Compare top extruded rubber suppliers now or ask our team for personalized recommendations based on your industry and application.

Frequently Asked Questions about Extruded Rubber

What are the most common materials used for extruded rubber products?

The most popular materials include EPDM (excellent weather and ozone resistance), neoprene (good oil and chemical resistance), silicone (high temperature stability and flexibility), nitrile (oil and fuel resistance), and natural rubber (great tensile strength and elasticity). The right choice depends on your application’s environmental and mechanical demands.

How are tolerances controlled in the rubber extrusion process?

Dimensional accuracy is managed through precise die design, controlled extrusion parameters, and post-extrusion curing. Manufacturers account for material swell or shrinkage by specifying plus/minus tolerances and using rigorous quality control measures.

Can I order custom extruded rubber profiles for unique applications?

Absolutely. Custom die design and formulation adjustments allow for the production of virtually any shape, including multi-cavity, hollow, solid, or co-extruded profiles. Many suppliers also offer value-added services such as adhesive backing, notching, or color matching.

What industries rely on extruded rubber products?

Virtually every sector uses extruded rubber, including automotive (seals, gaskets, hoses), construction (weatherstripping, glazing profiles), electrical (insulation, cable management), aerospace (vibration isolation, ducting), marine (hatch seals, bumpers), appliance, and medical device manufacturing.

How can I request a quote for extruded rubber products?

Use our simple RFQ form to contact multiple extruded rubber manufacturers at once. Be sure to provide detailed drawings, dimensions, material specifications, and anticipated quantities for the most accurate pricing and lead time estimates.

Get Expert Help with Your Extruded Rubber Needs

Whether you’re developing a new product, troubleshooting an existing application, or looking to optimize cost and performance, our network of experienced extruded rubber manufacturers and engineers can help. We offer comprehensive support from material selection and design through prototyping, production, and logistics.

Contact us today to:

- Request design assistance for custom extruded rubber profiles

- Compare suppliers and materials for your project

- Get fast, competitive quotes for prototyping or production orders

- Access technical resources and case studies

For additional information, download our extruded rubber buyer’s guide, explore industry-specific application notes, or chat live with a technical specialist to address your project’s specific requirements.

Ready to take the next step? Start your supplier search or submit your project details for a personalized consultation today.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services